Blankets for presses are all pure wool. Woven set comprises of one quality woven fronting blanket plus two felt padders. A combination set does for both Intaglio work and Relief . This includes Etching, Drypoint , Monoprint as well as Collographs ,Lino and Woodcuts.

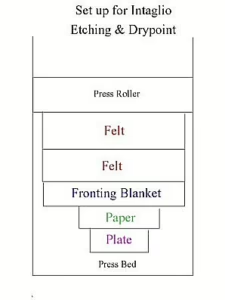

Intaglio work requires the the woven fronting blanket next to the paper with the felts on top.

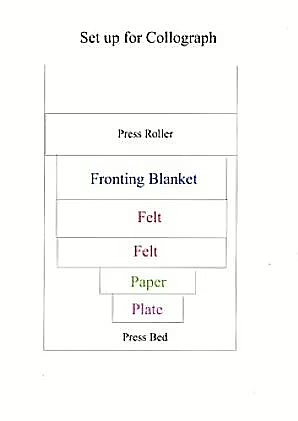

For Relief work the felts can be placed next to the paper and this is good for Collographs,Linocuts and Woodcuts.

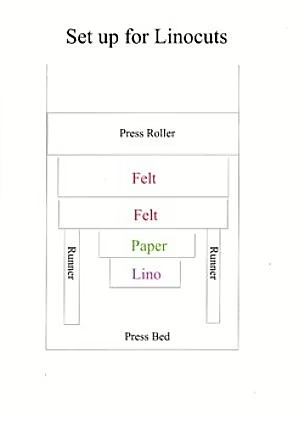

For Lino and Woodcut I recommend using just the two felts. When using blankets its good to put tissue or newsprint between paper and blanket . This is to absorb starch from the damp paper. Blanket set prices can be found at our Press Prices Page.

Blanket sets have a 12mm clearance at the sides and 25mm at the ends.

Blankets- the set up for our etching presses

Blankets information

Blankets set up for different Print types. From the bed we have the prepared plate , then dampened paper. Next the Blanket for the print type, followed by padder blankets. Intaglio printing needs a dense blanket with a smooth surface. I provide a woven wool blanket of very high quality. Sourced from the finest English wool weavers The felts are high quality also . Two Felts come in the blanket set , this makes the set more flexible. European sourced and regarded as clean. I don’t supply Swan Skins and regard them as a blanket to serve only one purpose, to be a padder. Collographs can be printed using Felts. I believe our etching presss are the best value and quality for modern printing and as such we provide only the best quality blankets for them.

Felts may be used to print Linocuts. Another method is using mounting card . the operator would need to apply the correct pressure. The diagram below explains the use of runners when doing relief work on a roller press. Relief work needs less pressure to produce the print,this may cause problems when mounting the work. To mount the work positively, runners may placed along side the work and extending beyond the work . This will allow pre- loaded pressure on the runners and not on the work. A smooth printing operation can then ensue. Runners must be the same height as the work. This prevents the print from embossing. Strips of the lino if its a linocut would do.The same principle would apply to woodcuts.

Lino set up on the press bed